Our Pumps.

We have an end-to-end production facility for manufacuring our pumps. From furnaces to testing, it's an exclusive facility. We have state-of-the-art Lathes, CNC lathes, Drilling machines, Milling machines, Balancing machines and Boring machines. We follow ISI / ASME / DIN / BS Standards.

Heavy Duty Slurry Pumps

Phosphoric acid filter feed and rock slurry in High Alloys. MOC: Sanicro 28 / Hastalloy G-30

Impeller capacity 0.5 m³/hr to 6000 m³/hr

Filter Feed Pumps

Phosphoric acid filter feed and rock slurry in High Alloys. MOC: Sanicro 28 / Hastalloy G-30

Capacity 500 m³/hr to 10000 m³/hr

Acid Slurry Pumps

Phosphoric acid filtration area, Copper/Zinc electrolyte circulation. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000

Capacity 5 m³/hr to 8000 m³/hr

P/N & P/R NPK/DAP Slurry Pumps

Steam jacketed design both grow on suction side. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000

Capacity 10 m³/hr to 500 m³/hr @ 50 kg / cm² to 150 kg / cm²

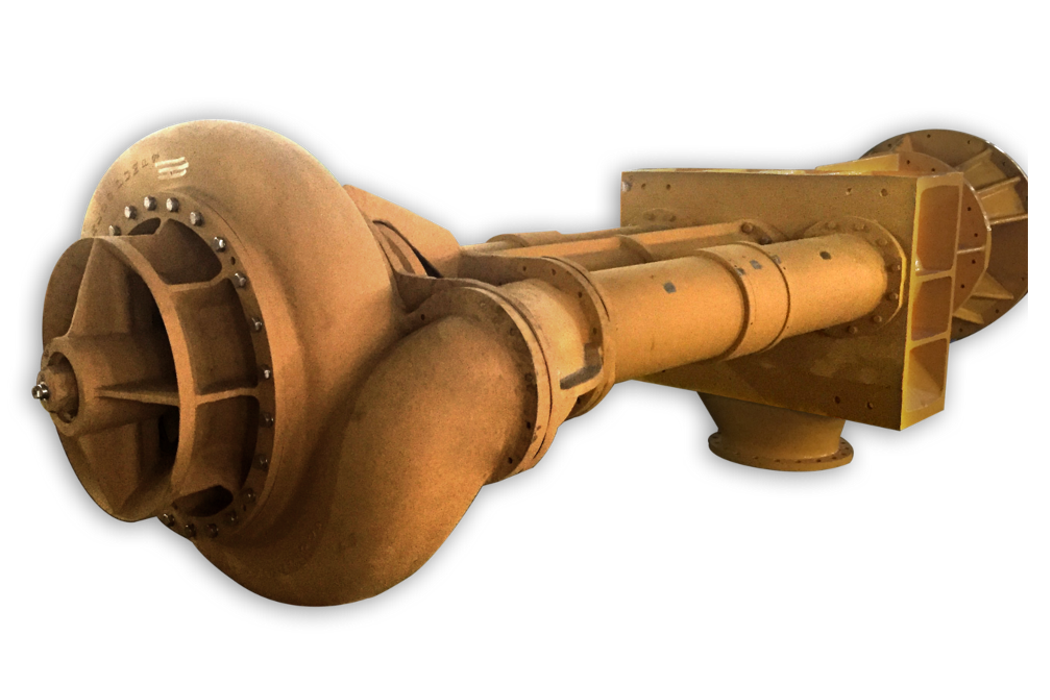

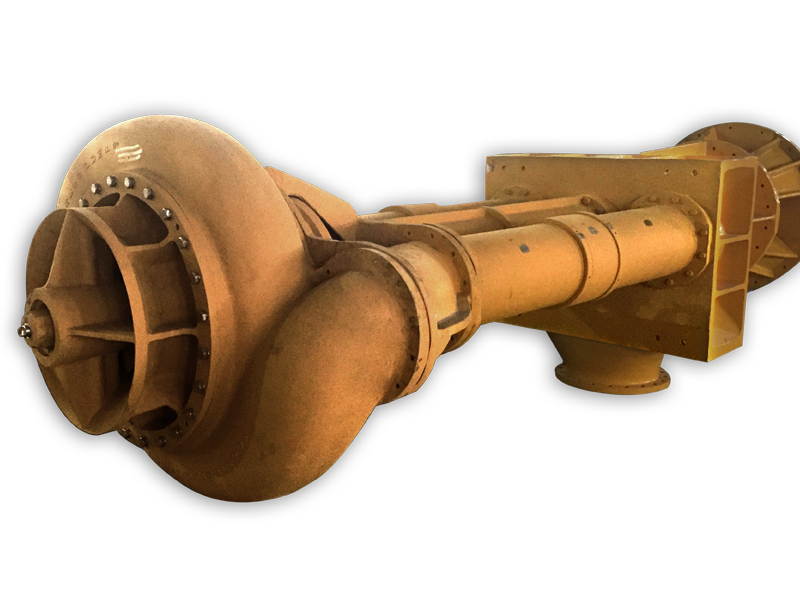

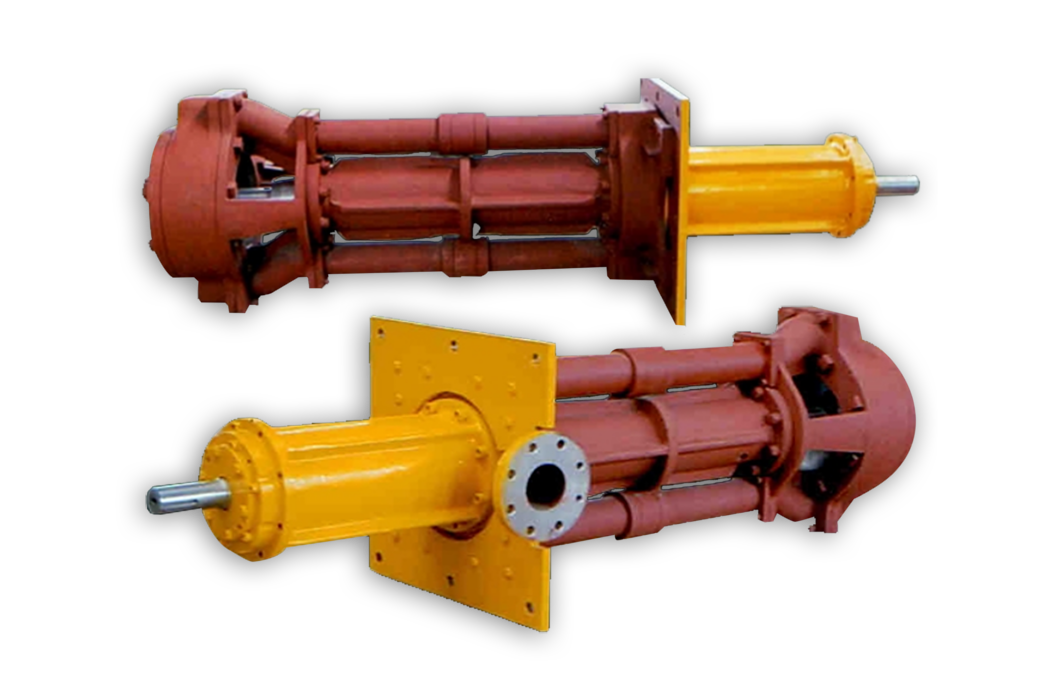

Axial Flow Circulation (Vertical & Horizontal) Pumps

Phosphoric acid vacuum rotor circulation, low levels flush cooler, evaporator circulation. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000, G-30, 9042

Opposed Impellers Multistage Barrel Pumps

High temperature hydrocarbons BFW applications

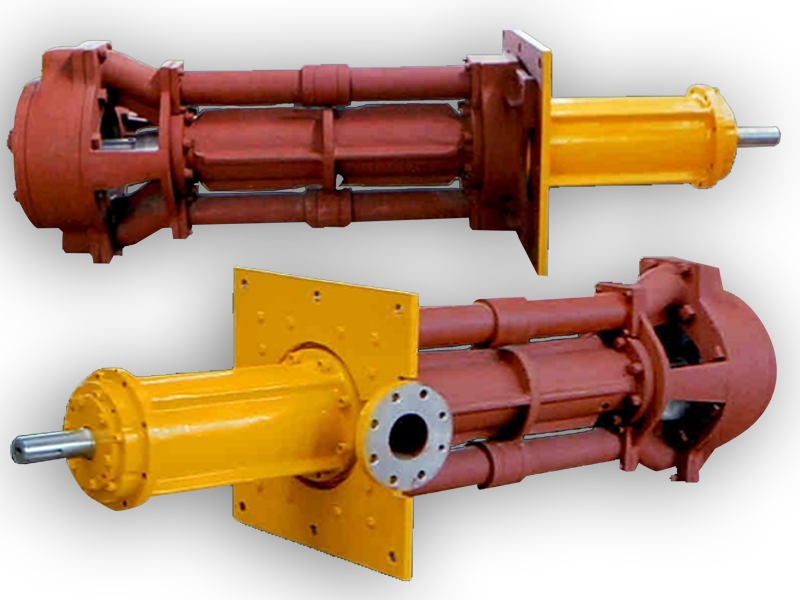

Vertical Phosphoric Acid Pumps

Double suction, double discharge style shaft overhang design. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000, G-30

Horizontal High Capacity Pumps

Phosphoric acid cold well/hot well, Copper/Zinc plant circulation, pulp & paper stock applications. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000, G-30

Acid Sludge Pumps

Phosphoric acid transfer/Sludge/Filtration area, Copper/Zinc, pulp & paper 4-5% consistency applications. MOC: Duplex steel / Sanicro 28 / Hastalloy C-2000, G-30

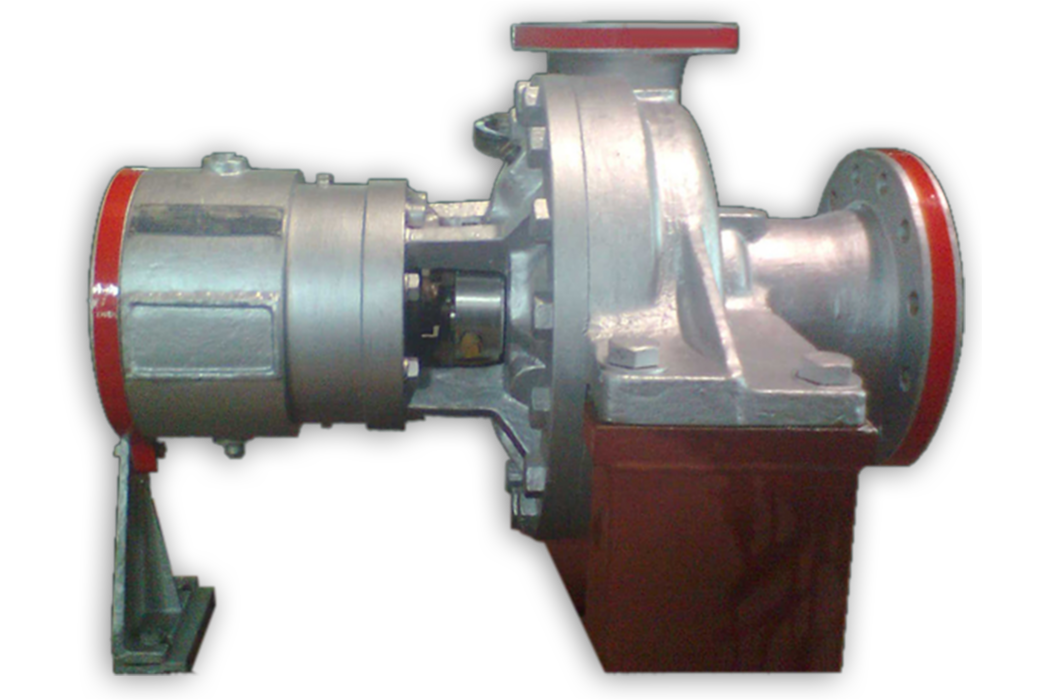

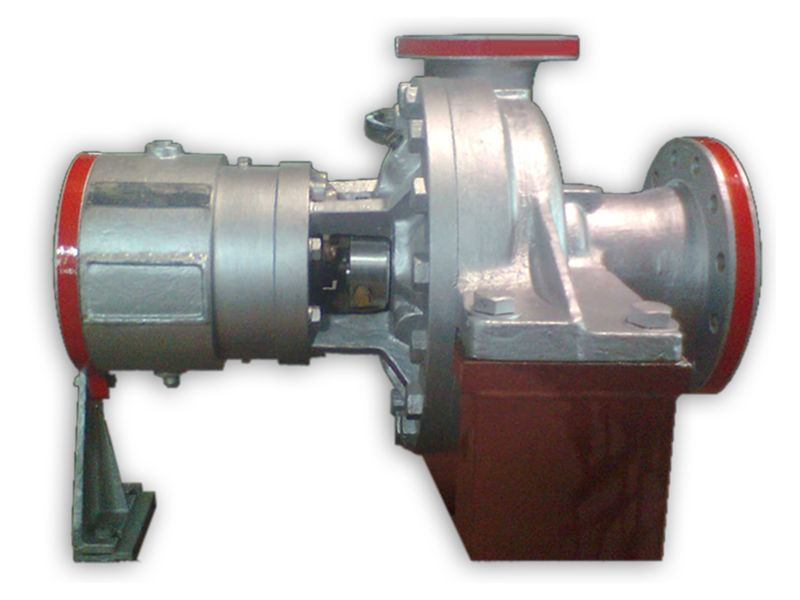

Horizontal Process Pumps

Both closed and open impellers for acids, chemicals, White/Black liquor applications

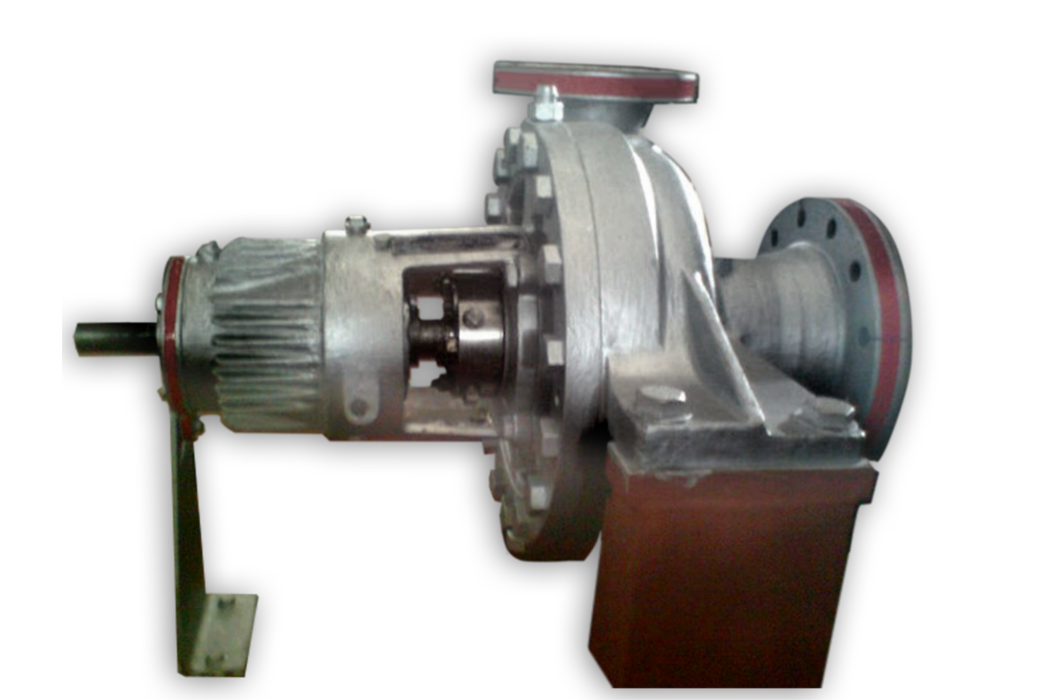

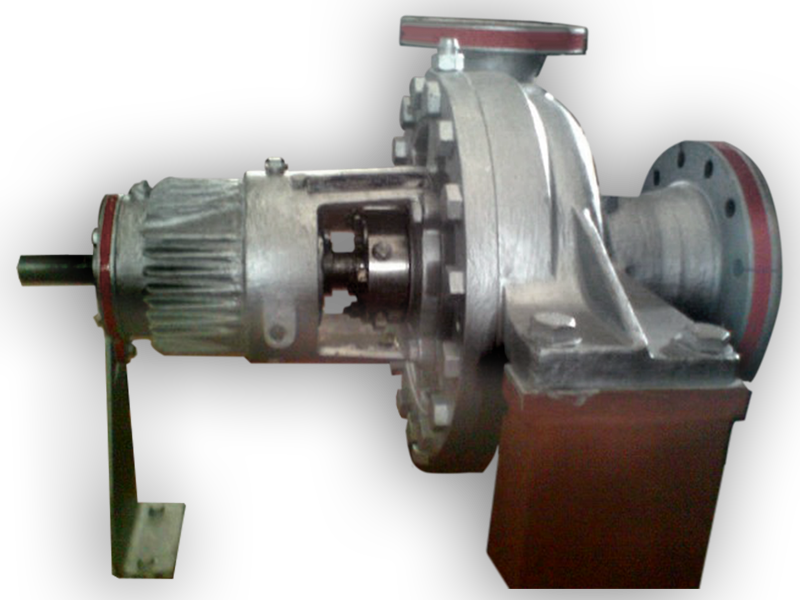

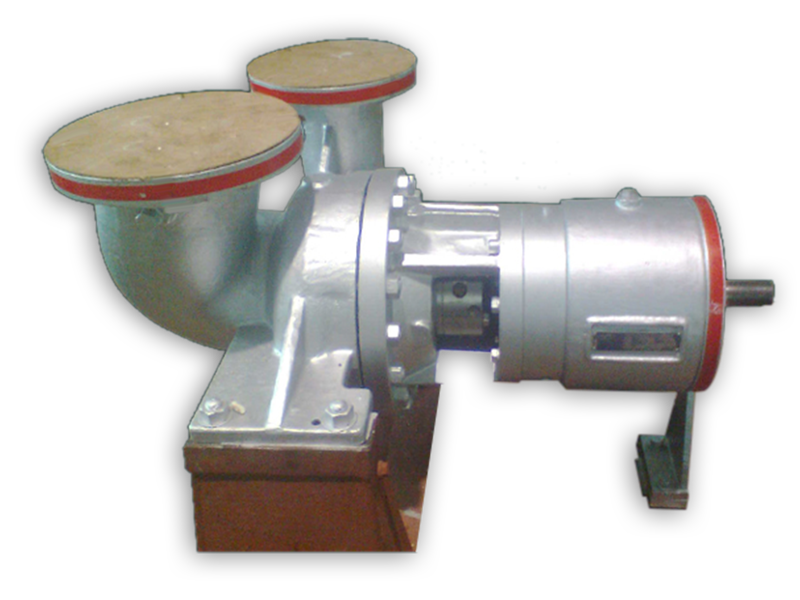

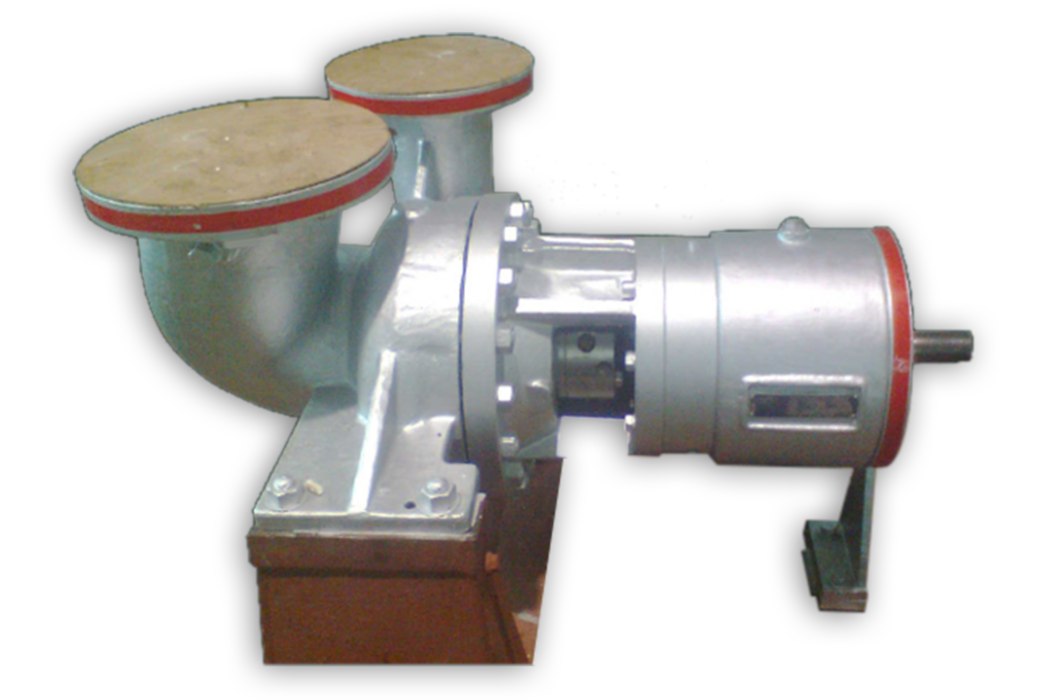

In-Built vacuum rotor MC 12-14% stock Pumps

In-Built vacuum rotor MC 12-14% stock Pumps. Both closed and open impellers for acids, chemicals, White/Black liquor applications

API-610 Centre Supported Bark Pull-out Pumps

High temperature petrochemicals, pulp digesters, black liquor applications

Water Jacketed API-610 10th Edition Pumps

High temperature refinery applications with temperature above 150oC

15. API-610 10th Edition Pumps

High temperature refinery applications with temperature below 150oC

JIFCO - Jordan

JIFCO - Jordan